Microwave Sensor Systems for Food and Beverage Applications

Quality parameters that can be measured:

- Moisture or Other Key Ingredient Content

- Liquid Fill Levels

- Certain Texture Characteristics

Advantages of Microwave Sensing for Food & Beverage Testing:

Non-contact measurements

Real-time monitoring

In-line quality control

Non-destructive

Measures through packaging

Key Microwave Sensor System Components

Examples of Measurements

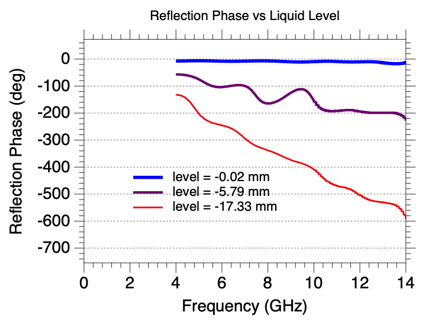

Quality Monitoring

- Reflection phase very sensitive to fill level of liquid in bottle

- Measures through bottle, even optically opaque

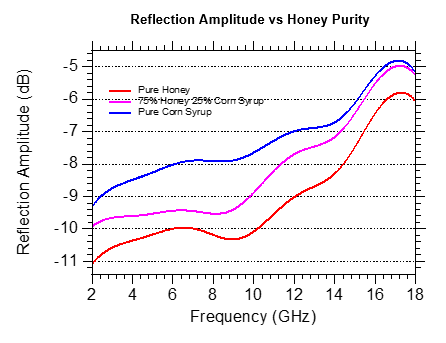

Purity Detection

- Reflection amplitude sensitive to proportion of honey vs corn syrup

- Can detect counterfeit honey

How We Can Work Together:

- You bring the problem and RF expertise. We bring the analyzer.

- You bring the problem. We bring the analyzer and RF expertise.